We created our recipe by taking advantage of the olive’s miracle.

The journey begins with grinding the olive pomace to an acceptable particle size.

To protect nature and life, solvent haven't been used in the patented formula we developed.

More budget-friendly compared to similar products in the market.

Created from plant- based waste and recycled materials. Oleatex itself can also be recycled!

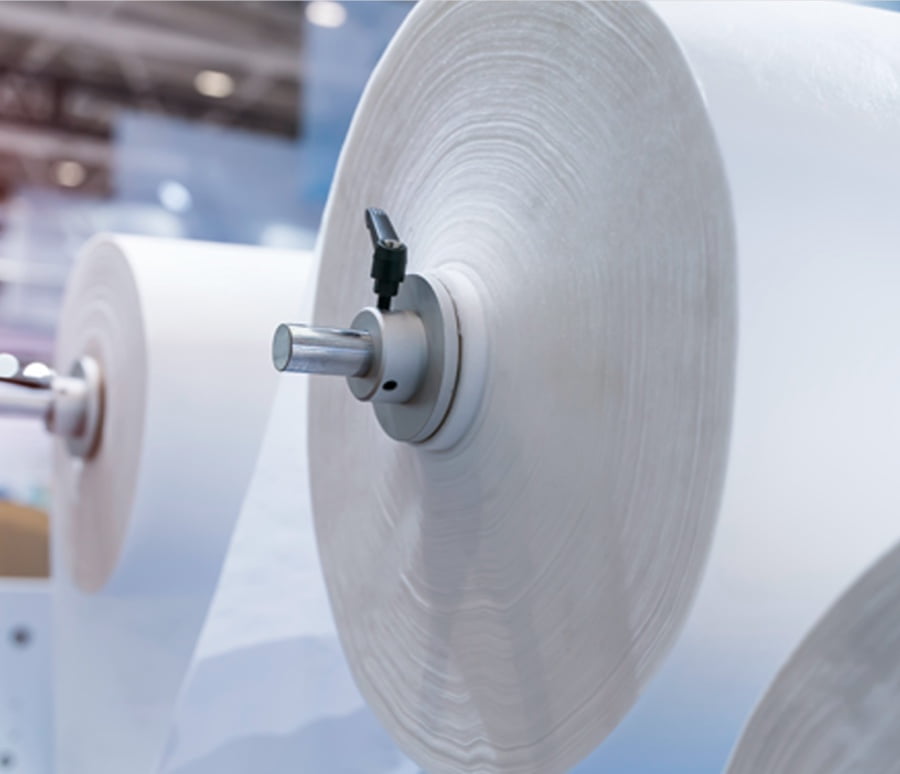

Supporting all 3 criteria of The Fashion Pact, Oleatex can be produced in large quantities.

As durable as real and artificial leather. In addition, requested performance features can also be added.

Reducing carbon footprint more than six times, No water usage. All bio-wastes are locally sourced. The whole process takes place within a radius of 100 km

Depending on the application area, it can be applied at required thickness, pattern, and color.

- We disrupt the olive industry cycle by taking their waste product and feeding it back into the manufacturing cycle.

- Oleatex offsets the carbon emission of the leather industry, cuts down on genuine and synthetic leather use - which in return cuts down on use of harmful chemicals and materials